close

Choose Your Site

Global

Social Media

| Place of Origin: | China |

|---|---|

| Brand Name: | PioneerTEX |

| Certification: | ISO9001 & ISO14001 |

| Model Number: | GEOMEMBRANE |

| Minimum Order Quantity: | 2000SQM |

| Price: | 0.5-1.5 US$/SQM |

| Packaging Details: | Standard exporting packaging |

| Delivery Time: | 2-3WEEKS |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 2000sqm/day |

| Availability: | |

|---|---|

| Quantity: | |

PIOLINER

PIONEERTEX

| Width: | 7.0mts | Color: | Black |

|---|---|---|---|

| Material: | HDPE | Name: | Pond Reservior Landfill Tunnel Smooth Hdpe Composite Geomembrane |

| Use: | Pond Reservior Landfill Tunnel | ||

| High Light: | Hdpe Composite Geomembrane,Reservior Composite Geomembrane,Pond Composite Geomembrane | ||

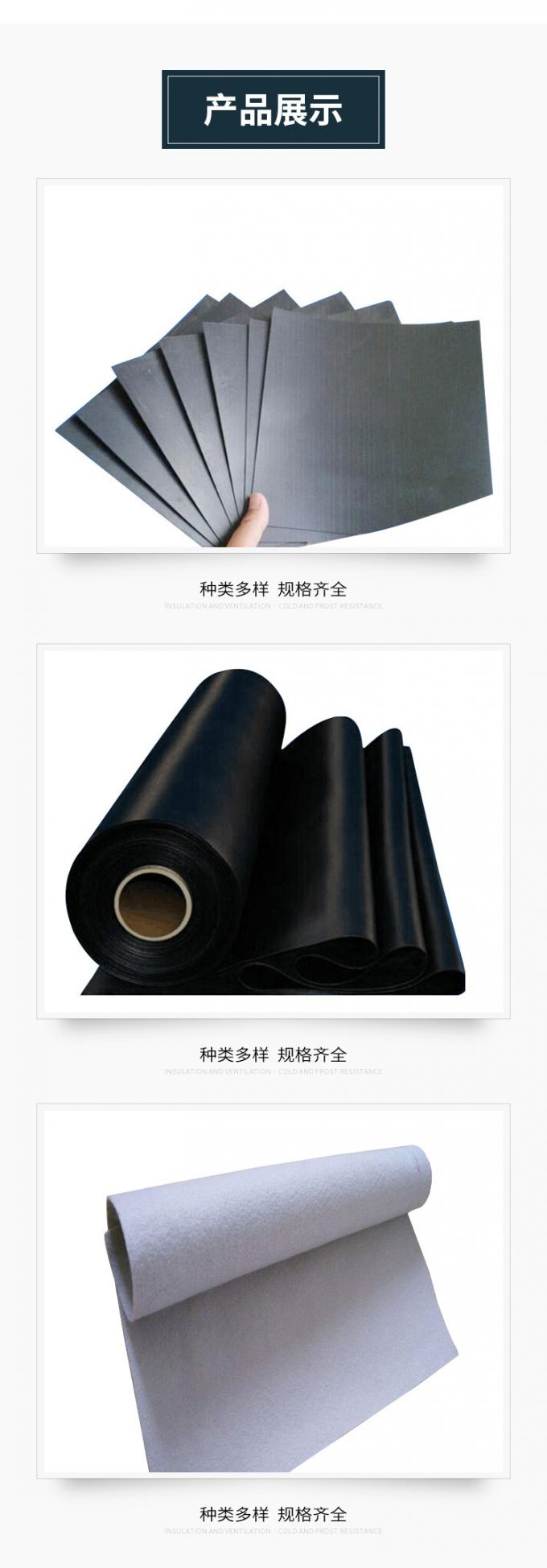

SMOOTH HDPE GEOMEMBRANE FOR WATERPROOF PROJECT( POND, RESERVIOR, LANDFILL AND TUNNEL)

HDPE Geomembrane liner are made from polyethylene polymer materials that blow molding,its main function is to prevent the liquid leakage and gas volatile.According to the production of raw materials can divide into HDPE geomembrane liner and EVA geomembrane liner,etc.

Product Application

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

| SMOOTH HDPE GEOMEMBRANE | |||||

| Property | Test Method | 40 Mil 1.0mm | 60 Mil 1.5mm | 80 Mil 2.0mm | 100 Mil 2.5mm |

| Thickness, mils | ASTM D 5199 | ||||

| minimum average | 40 | 60 | 80 | 100 | |

| lowest individual reading | 36 | 54 | 72 | 90 | |

| Sheet Density, g/cc | ASTM D 1505/D 792 | 0.94 | 0.94 | 0.94 | 0.94 |

| Tensile Properties 1 | ASTM D 6693 | ||||

| 1. Yield Strength, lb/ in | 84 | 126 | 168 | 210 | |

| 2. Break Strength, lb/ in | 152 | 228 | 304 | 380 | |

| 3. Yield Elongation, % | 12 | 12 | 12 | 12 | |

| 4. Break Elongation, % | 700 | 700 | 700 | 700 | |

| Tear Resistance, lb | ASTM D 1004 | 28 | 42 | 56 | 70 |

| Puncture Resistance, lb | ASTM D 4833 | 72 | 108 | 144 | 180 |

| Stress Crack Resistance 2, hrs | ASTM D 5397 (App.) | 300 | 300 | 300 | 300 |

| Carbon Black Content 3, % | ASTM D 1603 | 2.0 - 3.0 | 2.0 - 3.0 | 2.0 - 3.0 | 2.0 - 3.0 |

| Carbon Black Dispersion 4 | ASTM D 5596 | ||||

| Oxidate Induction Time (OIT) | |||||

| Standard OIT, minutes | ASTM D 3895 | 100 | 100 | 100 | 100 |

| Oven Aging at 85°C | ASTM D 5721 | ||||

| High Pressure OIT | ASTM D 5885 | 80 | 80 | 80 | 80 |

| (% retained after 90 days) | |||||

| UV Resistance 5 | GRI GM11 | ||||

| High Pressure OIT 6 | ASTM D 5885 | 50 | 50 | 50 | 50 |

| (% retained after 1600 hrs) | |||||

| Seam Properties | ASTM D 6392 | ||||

| (@ 2 in/min) | |||||

| 1. Shear Strength, lb/ in | 80 | 120 | 160 | 200 | |

| 2. Peel Strength, lb/ in - Hot Wedge | 60 | 91 | 121 | 151 | |

| - Extrusion Fillet | 52 | 78 | 104 | 130 | |

| Roll Dimensions | |||||

| 1. Width (feet): | 23 | 23 | 23 | 23 | |

| 2. Length (feet) | 750 | 500 | 375 | 300 | |

| 3. Area (square feet): | 17,250 | 11,500 | 8,625 | 6,900 | |

| 4. Gross Weight (pounds, approx.) | 3,470 | 3,470 | 3,470 | 3,470 | |

| Width: | 7.0mts | Color: | Black |

|---|---|---|---|

| Material: | HDPE | Name: | Pond Reservior Landfill Tunnel Smooth Hdpe Composite Geomembrane |

| Use: | Pond Reservior Landfill Tunnel | ||

| High Light: | Hdpe Composite Geomembrane,Reservior Composite Geomembrane,Pond Composite Geomembrane | ||

SMOOTH HDPE GEOMEMBRANE FOR WATERPROOF PROJECT( POND, RESERVIOR, LANDFILL AND TUNNEL)

HDPE Geomembrane liner are made from polyethylene polymer materials that blow molding,its main function is to prevent the liquid leakage and gas volatile.According to the production of raw materials can divide into HDPE geomembrane liner and EVA geomembrane liner,etc.

Product Application

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

| SMOOTH HDPE GEOMEMBRANE | |||||

| Property | Test Method | 40 Mil 1.0mm | 60 Mil 1.5mm | 80 Mil 2.0mm | 100 Mil 2.5mm |

| Thickness, mils | ASTM D 5199 | ||||

| minimum average | 40 | 60 | 80 | 100 | |

| lowest individual reading | 36 | 54 | 72 | 90 | |

| Sheet Density, g/cc | ASTM D 1505/D 792 | 0.94 | 0.94 | 0.94 | 0.94 |

| Tensile Properties 1 | ASTM D 6693 | ||||

| 1. Yield Strength, lb/ in | 84 | 126 | 168 | 210 | |

| 2. Break Strength, lb/ in | 152 | 228 | 304 | 380 | |

| 3. Yield Elongation, % | 12 | 12 | 12 | 12 | |

| 4. Break Elongation, % | 700 | 700 | 700 | 700 | |

| Tear Resistance, lb | ASTM D 1004 | 28 | 42 | 56 | 70 |

| Puncture Resistance, lb | ASTM D 4833 | 72 | 108 | 144 | 180 |

| Stress Crack Resistance 2, hrs | ASTM D 5397 (App.) | 300 | 300 | 300 | 300 |

| Carbon Black Content 3, % | ASTM D 1603 | 2.0 - 3.0 | 2.0 - 3.0 | 2.0 - 3.0 | 2.0 - 3.0 |

| Carbon Black Dispersion 4 | ASTM D 5596 | ||||

| Oxidate Induction Time (OIT) | |||||

| Standard OIT, minutes | ASTM D 3895 | 100 | 100 | 100 | 100 |

| Oven Aging at 85°C | ASTM D 5721 | ||||

| High Pressure OIT | ASTM D 5885 | 80 | 80 | 80 | 80 |

| (% retained after 90 days) | |||||

| UV Resistance 5 | GRI GM11 | ||||

| High Pressure OIT 6 | ASTM D 5885 | 50 | 50 | 50 | 50 |

| (% retained after 1600 hrs) | |||||

| Seam Properties | ASTM D 6392 | ||||

| (@ 2 in/min) | |||||

| 1. Shear Strength, lb/ in | 80 | 120 | 160 | 200 | |

| 2. Peel Strength, lb/ in - Hot Wedge | 60 | 91 | 121 | 151 | |

| - Extrusion Fillet | 52 | 78 | 104 | 130 | |

| Roll Dimensions | |||||

| 1. Width (feet): | 23 | 23 | 23 | 23 | |

| 2. Length (feet) | 750 | 500 | 375 | 300 | |

| 3. Area (square feet): | 17,250 | 11,500 | 8,625 | 6,900 | |

| 4. Gross Weight (pounds, approx.) | 3,470 | 3,470 | 3,470 | 3,470 | |