close

Choose Your Site

Global

Social Media

| Place of Origin: | Jiangsu,China |

|---|---|

| Brand Name: | PioneerTEX |

| Certification: | ISO9001 |

| Model Number: | PPFW |

| Minimum Order Quantity: | 2000SQM |

| Price: | 0.72 US$/SQM |

| Packaging Details: | pp woven |

| Delivery Time: | 2-3weeks |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5000 SQM/WEEK |

| Quantity: | |

|---|---|

| Material: | PP Tape Yarn And Round Yarn | Width: | 3.8mts |

|---|---|---|---|

| Color: | Black | Weight: | 200gsm,250gsm,300gsm |

| Length: | 200mts Per Roll | Thickness: | 0.2-0.5mm |

| High Light: | Woven Monofilament Geotextile,Geotextile Woven Filter Fabric,Geotextile Stabilization Fabric | ||

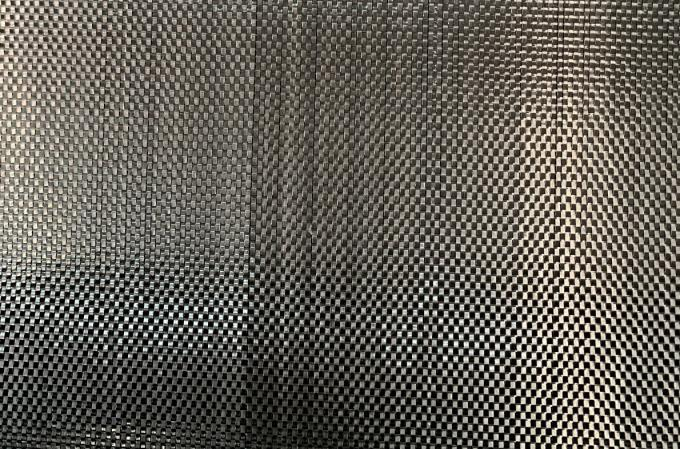

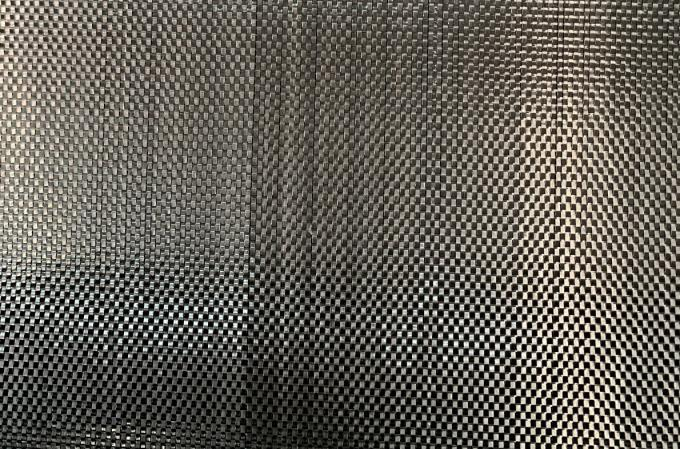

High Flow PP Woven Filter Geotextile fabric (Geo-mesh, geotextile mesh) with for landfill to prevent clogging

What is PP Woven filtration Geotextile Fabric-Geotextile mesh?

It is woven geotextile mesh made by polypropylene(PP) monofilament and tape yarn.

It is a permeable fabric material. It offers a combination of high strength and excellent hydraulic characteristics.

Woven Monofilaments are made from extruded monofilament (like fishing line) yarns woven into a screening.

Often times they are calendared, meaning a finishing heat is applied as it comes off the loom.

These are mainly used as filter fabrics in landfill drainage project, marine applications with fine grain sands, such as seawalls.

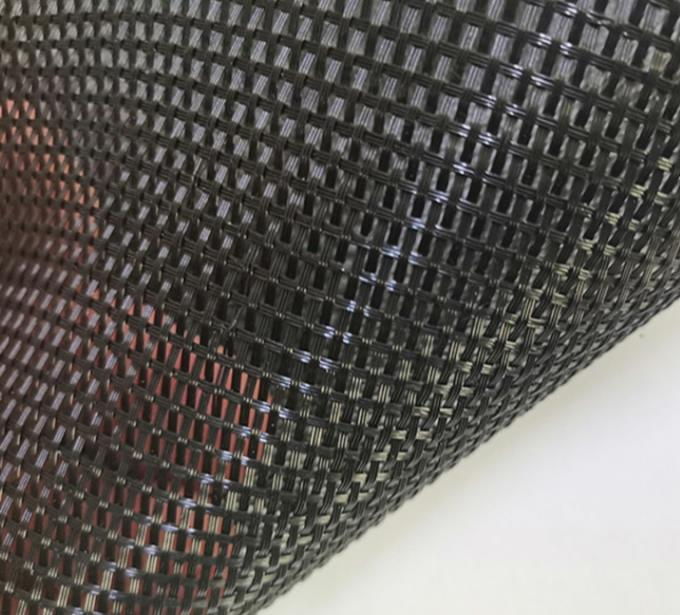

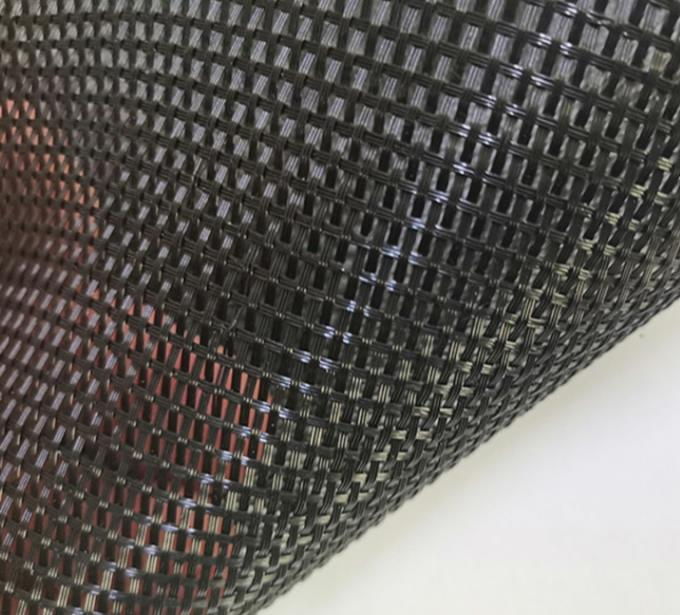

Filtration Geotextile Mesh Fabric Features:

These particular woven geotextiles have a high Percent Open Area (POA). Percent Open Area is the area of distinct, uniform and measurable openings in a filter fabric. The high POA of a monofilament woven geotextile assures that both water and problematic soil particles have direct paths through the fabric.

Nonwoven, woven slit-film and combination fabrics have little or no Percent Open Area compared to a woven, monofilament geotextile and therefore often trap soil particles and clog.Its performance can meet or exceed our national standard CJ/T 437-2013.

Technical Specification of PP Woven filtration/Filter | |||||

| ITEM | UNIT | WFG45/30 | WFG45/45 | WFG50/50 | |

| Mass per unit area | g/m2 | 200g | 240 | 270 | |

| Tensile Strength | MD | KN/M | 45 | 45 | 50 |

| CMD | KN/M | 30 | 45 | 50 | |

| Elongation at break | MD | % | 20 | 20 | 20 |

| CMD | % | 20 | 20 | 20 | |

| CBR Puncture strength | KN | 3.5 | 4.5 | 5.5 | |

| Strength retain % after UV | % | 85 | |||

| Opening Size( O95) | MM | 0.1-0.8 | |||

| POA | % | 4-12 | |||

Why Geotextiles Become Clogged:

To determine when a geotextile becomes clogged, a gradient ratio test is performed. Gradient ratio is defined as the ratio of the average hydraulic gradient across the fabric and the 1" of soil immediately next to the fabric, to the average hydraulic gradient across the 2" of soil between 1" and 3" above the fabric.

The US Army Corps of Engineers determined that if a gradient value exceeded 3, the fabric is considered clogged.

Tests were conducted to determine what geotextiles resisted clogging, based on the gradient ratio.

| Material: | PP Tape Yarn And Round Yarn | Width: | 3.8mts |

|---|---|---|---|

| Color: | Black | Weight: | 200gsm,250gsm,300gsm |

| Length: | 200mts Per Roll | Thickness: | 0.2-0.5mm |

| High Light: | Woven Monofilament Geotextile,Geotextile Woven Filter Fabric,Geotextile Stabilization Fabric | ||

High Flow PP Woven Filter Geotextile fabric (Geo-mesh, geotextile mesh) with for landfill to prevent clogging

What is PP Woven filtration Geotextile Fabric-Geotextile mesh?

It is woven geotextile mesh made by polypropylene(PP) monofilament and tape yarn.

It is a permeable fabric material. It offers a combination of high strength and excellent hydraulic characteristics.

Woven Monofilaments are made from extruded monofilament (like fishing line) yarns woven into a screening.

Often times they are calendared, meaning a finishing heat is applied as it comes off the loom.

These are mainly used as filter fabrics in landfill drainage project, marine applications with fine grain sands, such as seawalls.

Filtration Geotextile Mesh Fabric Features:

These particular woven geotextiles have a high Percent Open Area (POA). Percent Open Area is the area of distinct, uniform and measurable openings in a filter fabric. The high POA of a monofilament woven geotextile assures that both water and problematic soil particles have direct paths through the fabric.

Nonwoven, woven slit-film and combination fabrics have little or no Percent Open Area compared to a woven, monofilament geotextile and therefore often trap soil particles and clog.Its performance can meet or exceed our national standard CJ/T 437-2013.

Technical Specification of PP Woven filtration/Filter | |||||

| ITEM | UNIT | WFG45/30 | WFG45/45 | WFG50/50 | |

| Mass per unit area | g/m2 | 200g | 240 | 270 | |

| Tensile Strength | MD | KN/M | 45 | 45 | 50 |

| CMD | KN/M | 30 | 45 | 50 | |

| Elongation at break | MD | % | 20 | 20 | 20 |

| CMD | % | 20 | 20 | 20 | |

| CBR Puncture strength | KN | 3.5 | 4.5 | 5.5 | |

| Strength retain % after UV | % | 85 | |||

| Opening Size( O95) | MM | 0.1-0.8 | |||

| POA | % | 4-12 | |||

Why Geotextiles Become Clogged:

To determine when a geotextile becomes clogged, a gradient ratio test is performed. Gradient ratio is defined as the ratio of the average hydraulic gradient across the fabric and the 1" of soil immediately next to the fabric, to the average hydraulic gradient across the 2" of soil between 1" and 3" above the fabric.

The US Army Corps of Engineers determined that if a gradient value exceeded 3, the fabric is considered clogged.

Tests were conducted to determine what geotextiles resisted clogging, based on the gradient ratio.