close

Choose Your Site

Global

Social Media

| Place of Origin: | China |

|---|---|

| Brand Name: | PioneerTEX |

| Certification: | ISO9001 and ISO14001 |

| Model Number: | LVP |

| Minimum Order Quantity: | 2000SQM |

| Price: | 0.3-0.8 US$/SQM |

| Packaging Details: | PE FILM packaging outside |

| Delivery Time: | 3-4WEEKS |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 10000SQM/DAY |

| Availability: | |

|---|---|

| Quantity: | |

PIOLINER CM

PIONEERTEX

56031490

| Width: | 1.2m,1.5m,2m,4m | Length: | 100-200mts/Roll |

|---|---|---|---|

| Structure: | PP+PE+PP | Material: | PP+PE or PP+PE+PP or PE+PP+PE |

| Color: | Black,white And Blue | Weight: | 90,100,110,130,150,200gsm |

| High Light: | Waterproof LLDPE Geomembrane Liner,200gsm LLDPE Geomembrane Liner,Fish Pond LLDPE Composite Geomembrane | ||

PP Woven Coated PE Geo-Membrane Composite

PioneerTEX Composite Geomembrane specification.pdf...

PioneerTEX Composite Geomembrane Brochure.pdf

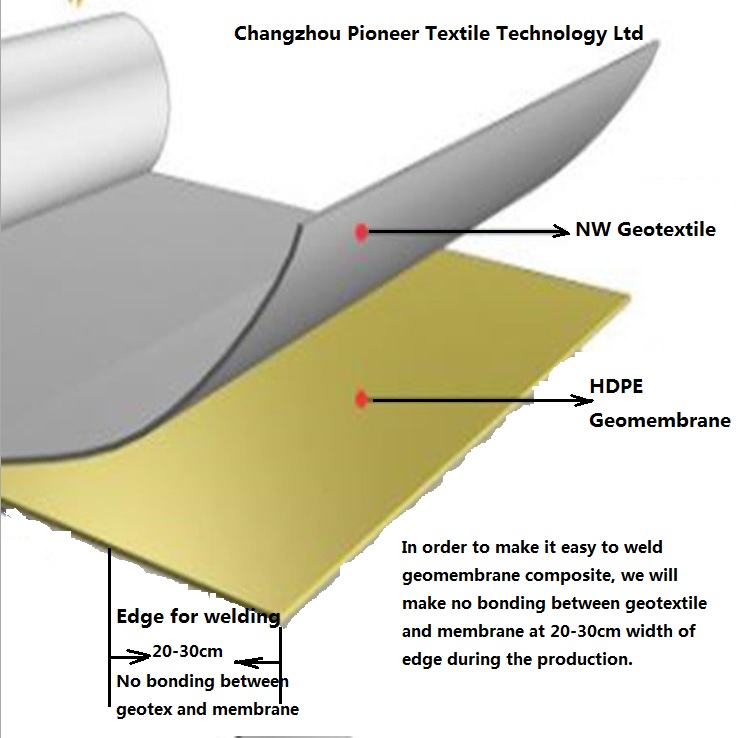

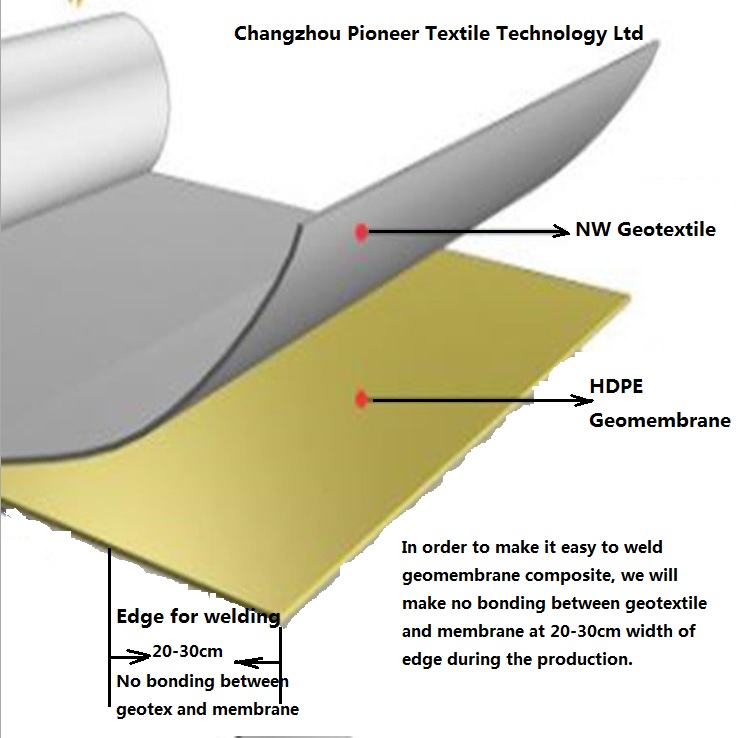

Composite geomembrane is made of geotextile (base fabric can be filament or short fiber needle punched geotextile ,woven geotextile ) and high polymer by calendering and hot-melt technology .

The composite geomembrane could remain the mechanical properties of base fabric and uniformity of film which improve the impermeability.

Embossed processing on the film strengthen its friction coefficient,stability and easy for installation .

Embossed processing on the film strengthen its friction coefficient,stability and easy for installation .

Composite Geomembranes provide over 300% higher puncture strength and over 200% higher tensile strength compared to the twice-as-thick, 60 mil HDPE.

Additionally, the prefabrication of Geomembranes allows for improved liner integrity and significantly reduces the number of field seams. HDPE is too rigid to prefab. Therefore, all seams are field seams, which translates into longer installation time, higher installation costs, and lower membrane integrity.

Composite Geomembrane liner special for liquid or gas barrier

1. Filament Needle Punch nonwoven geotextile :100-1000g/m2, or PP/PET woven geotextile

2. The thickness of LLDPE geo-membrane: 0.2mm --- 1.5mm,

3. Width: 1-6m ;

4. Reinforced Geotextile could also be woven geotextile such as PP woven or PET filament woven geotextile.

| Composite Geomembrane Liner Specification | ||||||||

| Test Properties | BCM4 | BCM5 | BCM6 | BCM7 | BCM8 | BCM9 | BCM10 | |

| Weight | g/m2 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| SPEC | 1 layer geotextile+ 1 layer membrane | 150/0.25 | 200/0.3 | 300/0.3 | 300/0.4 | 300/0.5 | 400/0.5 | 400/0.6 |

| 2 layer geotextile+ 1 layer membrane | 100/0.2/100 | 100/0.3/100 | 150/0.3/150 | 200/0.3/200 | 200/0.4/200 | 200/0.5/200 | 250/0.5/250 | |

| Mechanical Properties | Break Strength (KN/M) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 |

| Break Elongation(%) | 30-100 | |||||||

| CBR Burst Strength(KN) | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3 | |

| Tear Strength(KN) | 0.15 | 0.25 | 0.32 | 0.4 | 0.48 | 0.56 | 0.64 | |

| Peel Strength(N/cm) | 6 | |||||||

| 1 layer geotextile+ 1 layer membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.3 | |

| 2 layer geotextile+ 1 layer membrane | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.5 | |

| Color | HDPE Geomembrane | BLACK or WHITE | ||||||

| Nonwoven Geotextile | BLACK or WHITE | |||||||

| Woven Geotextile | BLACK or WHITE | |||||||

| ROLL DIMENSION | ||||||||

| Width | 1-6m | |||||||

| Length | 50-200m/Roll | |||||||

| Width: | 1.2m,1.5m,2m,4m | Length: | 100-200mts/Roll |

|---|---|---|---|

| Structure: | PP+PE+PP | Material: | PP+PE or PP+PE+PP or PE+PP+PE |

| Color: | Black,white And Blue | Weight: | 90,100,110,130,150,200gsm |

| High Light: | Waterproof LLDPE Geomembrane Liner,200gsm LLDPE Geomembrane Liner,Fish Pond LLDPE Composite Geomembrane | ||

PP Woven Coated PE Geo-Membrane Composite

PioneerTEX Composite Geomembrane specification.pdf...

PioneerTEX Composite Geomembrane Brochure.pdf

Composite geomembrane is made of geotextile (base fabric can be filament or short fiber needle punched geotextile ,woven geotextile ) and high polymer by calendering and hot-melt technology .

The composite geomembrane could remain the mechanical properties of base fabric and uniformity of film which improve the impermeability.

Embossed processing on the film strengthen its friction coefficient,stability and easy for installation .

Embossed processing on the film strengthen its friction coefficient,stability and easy for installation .

Composite Geomembranes provide over 300% higher puncture strength and over 200% higher tensile strength compared to the twice-as-thick, 60 mil HDPE.

Additionally, the prefabrication of Geomembranes allows for improved liner integrity and significantly reduces the number of field seams. HDPE is too rigid to prefab. Therefore, all seams are field seams, which translates into longer installation time, higher installation costs, and lower membrane integrity.

Composite Geomembrane liner special for liquid or gas barrier

1. Filament Needle Punch nonwoven geotextile :100-1000g/m2, or PP/PET woven geotextile

2. The thickness of LLDPE geo-membrane: 0.2mm --- 1.5mm,

3. Width: 1-6m ;

4. Reinforced Geotextile could also be woven geotextile such as PP woven or PET filament woven geotextile.

| Composite Geomembrane Liner Specification | ||||||||

| Test Properties | BCM4 | BCM5 | BCM6 | BCM7 | BCM8 | BCM9 | BCM10 | |

| Weight | g/m2 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| SPEC | 1 layer geotextile+ 1 layer membrane | 150/0.25 | 200/0.3 | 300/0.3 | 300/0.4 | 300/0.5 | 400/0.5 | 400/0.6 |

| 2 layer geotextile+ 1 layer membrane | 100/0.2/100 | 100/0.3/100 | 150/0.3/150 | 200/0.3/200 | 200/0.4/200 | 200/0.5/200 | 250/0.5/250 | |

| Mechanical Properties | Break Strength (KN/M) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 |

| Break Elongation(%) | 30-100 | |||||||

| CBR Burst Strength(KN) | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3 | |

| Tear Strength(KN) | 0.15 | 0.25 | 0.32 | 0.4 | 0.48 | 0.56 | 0.64 | |

| Peel Strength(N/cm) | 6 | |||||||

| 1 layer geotextile+ 1 layer membrane | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.3 | |

| 2 layer geotextile+ 1 layer membrane | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.5 | |

| Color | HDPE Geomembrane | BLACK or WHITE | ||||||

| Nonwoven Geotextile | BLACK or WHITE | |||||||

| Woven Geotextile | BLACK or WHITE | |||||||

| ROLL DIMENSION | ||||||||

| Width | 1-6m | |||||||

| Length | 50-200m/Roll | |||||||